Lo3-40 gerador de ozônio esterilizador 40 g gerador de nitrogênio para alimentos

Descrição

Informação básica

| Doença | Novo |

| Certificação | RoHS, UR, ISO, CE, CCC |

| Tensão | 380V |

| garantia | 1 ano |

| Tipo | Montado em Skid/Contêiner |

| Pureza | 99-99,999% |

| Componentes do núcleo | PLC, Vaso de Pressão, Válvula Solenóide, Molecular |

| Serviço pós-venda | Engenheiros disponíveis para manutenção de máquinas no exterior, |

| Ponto de Orvalho do Nitrogênio | -40ºC |

| Vida de serviço | 10 anos |

| Pacote de transporte | Caixa/palete de madeira no padrão de exportação |

| Especificação | 1000*1200*1500 |

| Marca comercial | LDH |

| Origem | Pequim, China |

| Código SH | 841960 |

| Capacidade de produção | 500 |

Descrição do produto

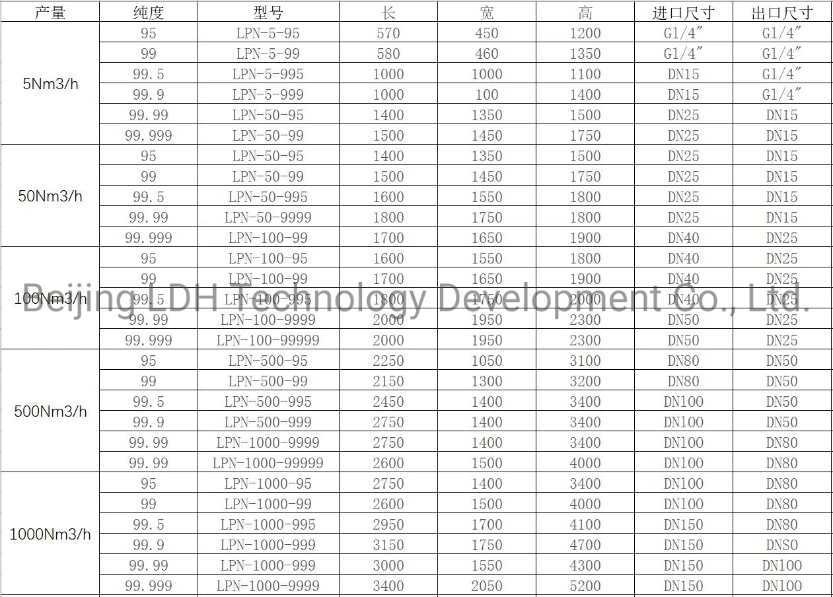

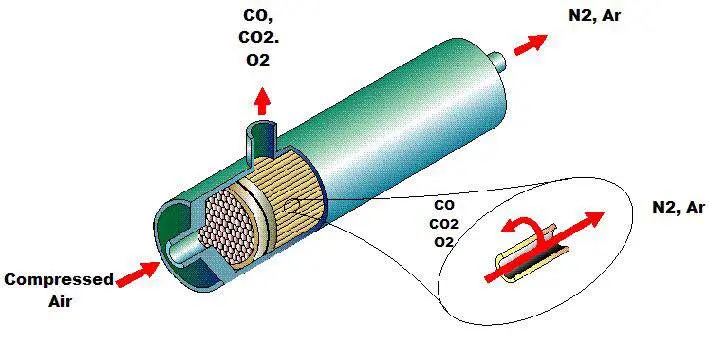

40m3/Hr Food Packaging Special Nitrogen Machine Purity 99.99%LDH GAS Systems é um fabricante chinês especializado em usinas de gás no local para geração de nitrogênio, geração de oxigênio, sistemas de purificação e assim por diante. Planta compacta de nitrogênio de alta pureza montada em skid Com mais de 100 sistemas construídos em todo o mundo desde 2017, os sistemas conquistam o respeito de todos com sua confiabilidade, economia, conveniência e nossos excelentes serviços.Uma família de sistemas LDH tem sido usada em uma ampla gama de indústrias: química e refino, produção de petróleo e gás, eletrônica, aeronáutica e aeroespacial, farmacêutico/saúde, alimentos, metalúrgico, vidro, mina de carvão e aquicultura. Os sistemas LDH são a personificação da síntese da tecnologia de ponta e das técnicas de fabricação perfeitas. Nosso objetivo é fornecer aos nossos cliente com sistemas de separação de ar LDH mais confiáveis, mais econômicos e mais convenientes e mais serviços profissionais. Gerador de nitrogênio PSA nome completo: Adsorção por oscilação de pressão (PSA). PSA é uma nova tecnologia de separação de gás, que foi desenvolvida rapidamente em países estrangeiros desde o final Década de 1960 e início dos anos 1970. Seu princípio é separar a mistura de gases pela diferença do desempenho de "adsorção" de diferentes moléculas de gás por peneira molecular. Leva o ar como matéria-prima. O nitrogênio e o oxigênio no ar são separados pela adsorção seletiva de nitrogênio e oxigênio com alta eficiência e alta seleção de adsorvente sólido.

3) Spare Parts ServiceWorldwide, quick and low-priced over the complete lifetime of your plant. The distinct tagging of all plant components delivered by us enables us to identify clearly the spare parts requested by you. We supply you with products designed for a long life and economic efficiency. For modifications and extensions we look for the most optimal and economic solution for your individual purpose. 4) Maintenance/RevisionsRegular inspection and maintenance ensures permanent operation, avoids damage and prevents unexpected breakdowns. In the course of maintenance/revision works we check all relevant components for function and condition, exchange defect, used and worn parts and afterwards optimally eadjust your plant to the given operating conditions. Depending on the plant size and scope of work, our service range comprises also a detailed scheduling of revisions as well as coordination and supervision of contractors. As a matter of course we supply maintenance documentation in form of reports and spare part recommendations, and we coordinate our schedules according to your requirements. 5) TrainingKnow-how for your personnel. Operation, maintenance and repair, electric measuring and control equipment or process engineering - we offer you specific training by our experts. Whether on site working with theplant itself, or on our permises, we concentrate on your questions and problems. What is a Packaging Gas?Air contains approximately 78% nitrogen, 21% oxygen and a variable amount of moisture. When exposed to air, foods such as potato chips absorb moisture and go stale and soggy quickly. Atmospheric oxygen also reacts with the unsaturated fatty acids present in foods, resulting in rancid off-flavours. Consequently, it is always a challenge faced by food manufacturers in preserving the desirable quality and prolonging the shelf life of food products.The use of packaging gas is an effective solution. A packaging gas is a gas that is introduced into a package before, during or after filling with food to protect the food from oxidation or spoilage. Examples include nitrogen, carbon dioxide and nitrous oxide. Nitrogen has a long history of use as a packaging gas in various foods including snacks, breakfast cereals, candies, bakery products, dried fruits and vegetables, and processed meat products.Nitrogen Does More than a Packaging GasNitrogen has found its way to the brewery and coffee industries where nitrogen is infused in beer or cold brew coffee to make 'nitro beer' or 'nitro brew', giving the final product a richer and creamier mouthfeel.How does Nitrogen Work as a Packaging Gas?Unlike the air you breathe every second, nitrogen used in food packaging contains very little oxygen and moisture. Nitrogen is inert (i.e. not reacting with any food components), odourless and tasteless. When nitrogen is introduced into a package, it drives out oxygen and any moisture present. By modifying the atmosphere inside the package, food packaging with nitrogen preserves quality, slows down spoilage and extends the products' shelf life.Nitrogen also cushions and protects delicate foods inside the package from being crushed during handling. Nonetheless, the amount of nitrogen used should provide enough protection but not too much to allow space for additional expansion due to pressure changes in transit and during storage.The package, with low gas permeability, must be sealed tightly to prevent the nitrogen from escaping. Once you open the package, the food inside is exposed to atmospheric air containing oxygen and moisture. Without protection from an immediate, controlled environment, the contents are then prone to moisture pickup, spoilage and oxidation. Therefore, it is best to consume the food products as soon as possible once the package is opened.Food suppliers are always seeking ways to extend shelf life. Improved shelf life allows manufacturers to extend their geographical reach and allows the product to remain in stores and consumer's homes longer. Modified Atmosphere Packaging (MAP) is a technique commonly used in the food processing industry to extend shelf life. The MAP process involves displacing the air inside a package with a protective gas to keep oxygen at controlled levels (less than 2 percent). Too much oxygen and moisture in a package often leads to bacterial growth and oxidation resulting in spoilage, inconsistent flavors, poor product quality, and shortened shelf life. Nitrogen is frequently used as a protective gas because of its dry, inert qualitiesSources of nitrogenNitrogen can be obtained from outside suppliers in the form of high-pressure tanks, dewars, or bulk liquid supply. Nitrogen can also be produced on-site using standard compressed air with an in-house nitrogen generator. An in-house generator separates nitrogen and oxygen from the air, and can often be the most efficient and economical method of supplying nitrogen for MAP applications.Disadvantages of a delivered nitrogen supplyRelying on outside vendors can pose several challenges including uncontrollable price increases, contract negotiations, tank rental fees, adherence to OSHA requirements, hazardous material fees, delivery surcharges, and local and state taxes. Problems such as scheduling conflicts, delivery delays, and lengthy procurement processes can slow down operations.This all adds up to extra administrative work and higher operational costs. The delivery approach also doesn't fit the trend toward lean production techniques and developing fewer, more efficient supply chains. Precautions must also be taken when handling and storing high pressure cylinders. A dangerous situation can be created if a cylinder is dropped and a valve is broken off, potentially causing the cylinder to become a projectile.Operational benefits of generating nitrogen on-siteGenerating your own supply of nitrogen in-house eliminates the challenges associated with outside vendors and ensures long-term cost stability. Generating nitrogen in-house is also good for the environment and represents a sustainable approach to supplying the gas. Producing nitrogen off site at fractional distillation plants and transporting it to end users is energy intensive and can result in large amounts of CO2 emissions.

Anterior: Secador de ar comprimido resfriado a ar refrigerado

Próximo: Gerador de oxigênio de alto desempenho para tratamento de água com ozônio

Nosso contato